Powder coating services

T2N powder coating specializes in electrostatic coating (or e-coating). Our expertise incorporates a wide range of powder coating applications: medical devices, automotive, architectural, agriculture and furniture. T2N stands out because of its great production flexibility which can accommodate parts of up to 22 ft. in length.

Automotive Powder Coatings

Powder coating occupies an important place in the automotive sector. Its corrosion resistance properties and its glossy finish are characteristics that are highly valued by this sector. T2N employs Zinc rich primer and durable clear top coat to the base color providing improved corrosion protection and gloss retention. T2N offers a wide choice of colors and finishes!

Architectural Powder Coatings

The architecture/building category includes possible applications on a variety of architectural elements such as railings, light poles, window frames, signs, posts, fencing and a variety of indoor and outdoor building components.

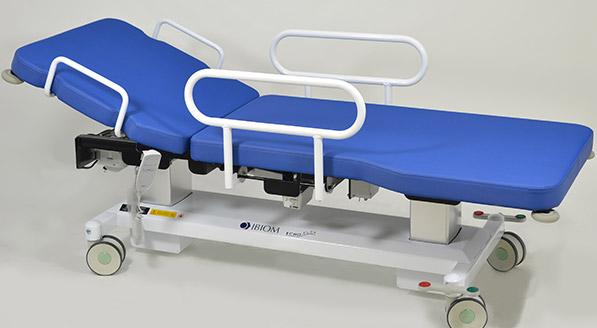

Medical Device Powder Coatings

We offer outstanding quality and durability for medical devices. We understand the importance of and need for durability in this type of equipment and this is why we strive to provide high quality powder coating. T2N is a key provider to Physipro Inc., wheelchair manufacturers, and Ibiom biomedical product manufacturers.

Furniture Powder Coatings

T2N offers coating services for indoor furniture to UV resistant coatings for patio furniture. We offer a wide choice of colors and texture coating to fit your needs.

ACE Powder Coatings

T2N provides agricultural, construction and earth-moving equipment powder coating services. For example, trailers, lawn mowers, railing, fencing, utility cabinets, planting, harvesting equipment, etc. Our UV and corrosion resistant coatings will ensure strong protection in various climatic conditions.

24H AND 48H SERVICE

Are you in a rush? T2N now offers a service that responds to your requests within 24 hours/48 hours only. Contact us to get a quote.

Additional charges apply. Maximum size per piece: 24 “x 24”.

About us

T2N powder coating experts are at your disposal to provide electrocoating services.

- A GROWING TECHNOLOGY

- WHAT IS POWDER COATING?

- WHY CHOOSE POWDER COATING?

- WHAT ARE THE ADVANTAGES OF POWDER COATING?

- 5-STAGES SURFACE TREATMENT

- BP8 ANTI-CORROSION TREATMENT

We only need to look at objects that are in our everyday life to realize the numerous possible applications of powder coating. This technology is growing steadily and its versatility allows for applications on thousands of metal products.

The decorative and functional characteristics of powder coating make it an efficient method. In addition to its beautiful and glossy finish, powder coating is resistant to chipping, scratching, fading and it provides a great protection from chemicals, corrosion and UV.

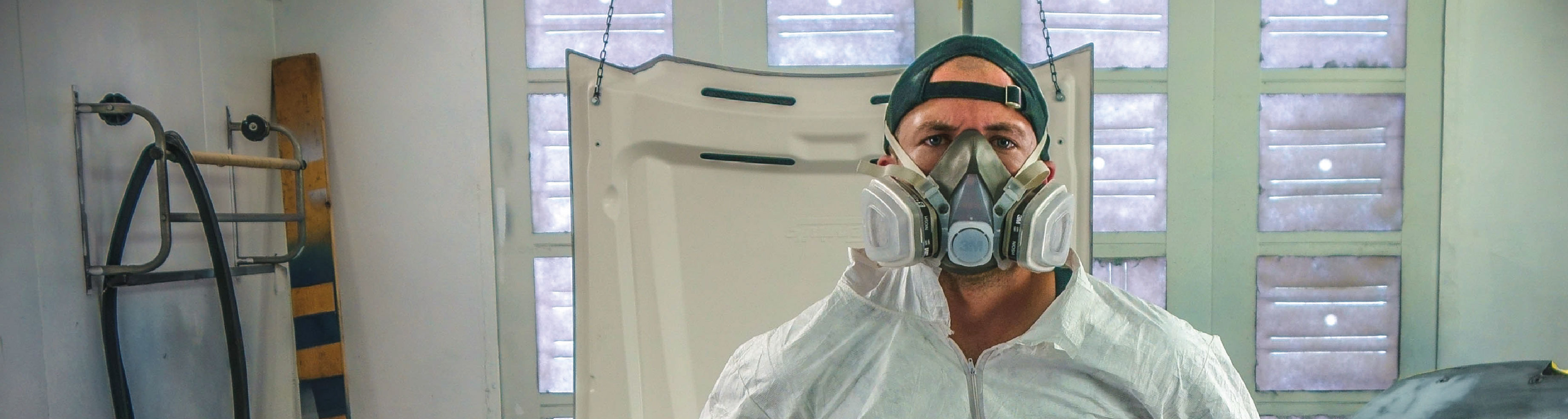

Powder coating is a dry finishing process that was developed as an alternative to liquid paint in the late 1960s. Unlike traditional liquid paint, powder coating doesn’t require any solvents. The application method of powder coating utilizes a spray gun, which applies an electrostatic charge to the powder particles, which are then attracted to the grounded part. The parts then enter a curing oven to a temperature of (120 à 240 °C) for a specific period of time to obtain smooth and hard surfaces.

COMMERCIAL ASSET

Since powder coating is becoming more and more an alternative to other finishing processes, OEMs highlight the superior coating property of powder coating in their marketing literature. It is a way to gain a competitive advantage!

PROVEN TRACK RECORD

Powder coating has been used in North America since the late 1960s. This finishing technology remains a segment that has experienced the most rapid growth amongst other finishing processes.

WE PASSED THE TEST!

Metal products and products containing metal components are regularly exposed to the elements. That is why it is imperative to ensure they have surface protection, so no matter the clime or place your products stay protected from corrosion. ASTM B117 Salt Spray (Fog) Test is often used to evaluate the relative corrosion resistance of coated and uncoated materials exposed to a salt spray or fog at an elevated temperature.

T2N is proud to announce that we have achieved outstanding results to the Salt Spray Test with a resistance of 1500 hours.

ENVIRONNEMENTAL IMPACT

Powder coatings are negligible VOC’S and HAPs (hazardous air pollutants) materials. It contains no solvents and therefore emit negligible, if any, polluting VOC’S into the atmosphere.

COATING PERFORMANCE

Powder coating has a remarkably better mechanical, corrosion, and chemical resistance when compared to all other organic finishes. Many manufacturers (OEMs) will choose powder coating to increase their products performance. This technology is known for its superior durability.

T2N is constantly innovating its processes to offer its customers professional quality products that will last for years. Therefore, a whole new technique for washing and preparing mixed metal surfaces is now being used to properly prepare metals to receive their final powder coating.

This technique consists of performing a 5-stages Zirconium chemical pre-treatment for ferrous and non-ferrous metals. With this technique, the metals are degreased, cleaned, removed from any trace of stains, and protected against corrosion.

This technique is specifically designed for mixed metals, like aluminium, cold-rolled steel, hot-rolled steel and zinc-plated steel. This surface treatment is also able to withstand up to 4,000 hours of salt spray (according to ASTM B117 standard) on aluminum.

T2N is proud to add this technique to its production stages, a wise choice to improve the quality of the finished product.

T2N: THE REAL ANTI-CORROSION EXPERT IN QUEBEC

In order to offer our customers the best in corrosion protection, T2N is proud to present BP8 Treatment, our all-new, 8-step surface treatment.

Meticulously designed and developed by the T2N team, the BP8 anti-corrosion treatment is an 8-step surface pretreatment process that involves coating a metal part with semi-gloss black paint applied electrostatically.

This 8-step process offers a number of advantages for your products:

- Coating 3.5 to 4.5 thousandths of an inch over the entire surface of the product

- Enhanced corrosion protection

- Coverage over sharp edges

- Coverage of tight spaces

The Best Corrosion Protection for Your Parts

To guarantee the best possible protection, the core of the BP8 8-step anti-corrosion treatment includes a zirconium chemical pretreatment and a paint with a 3000-hour salt-spray rating on steel (according to ASTM B117).

Moreover, T2N’s BP8 surface treatment opts for semi-gloss black paint as an alternative to high-zinc or zinc-free primers and as an effective single-coat solution as opposed to more costly two-coat systems.

The BP8 anti-corrosion treatment yields excellent weather resistance and can also be used with an application of electrostatic powder paint in the color of your choice!

Get in touch now with your T2N expert to take advantage of this very affordable corrosion protection.

Practical Applications of the BP8 Anti-Corrosion Treatment

- Agricultural equipment

- Household appliances

- Automotive parts

- Medical equipment

- Accessories

- Wheels

- Recreational and transportation vehicles

PROJECTS

INDUSTRIE FABCO

Architectural

Cunnington

Furniture

Ironbull Strenght

Strength EquipmentTESTIMONIALS

"We congratulate the group "T2N Powder Coating" for its success and are happy to contribute to it as a customer satisfied with their expertise, product quality, paint application, and especially the respect of deliveries according to our deadlines. Therefore, we recommend T2N for all powder coating on metal parts or other surfaces." INDUSTRIE DELACORP INC.

- Nicol Depot, Président

"Attention to detail is a prime criterion for Milan Design. T2N has met our expectations from the outset and has delivered a service of excellence. "

Yvan Hewus, ing. jr. Ingénieur de projet - Project Engineer

" We are very pleased to be working with T2N because of the special attention that is given to each of our products. Each part is handled with extreme care at every step of the way. This leads to a flawless result. " Les Entreprises Vimax Inc.

- Frédéric Viton, Chargé de projet

"We are very happy to do business with T2N. They offer a service customized to our company which is specialized in medical device manufacturing. T2N succeeds in achieving the very high quality standard we aspire. " Physipro inc.

- Jayson Ouellette, Directeur adjoint

GET A QUOTE

Please fill out the form below to contact us.

Tell us about your project, timeline and budget. Whatever the nature of your project, simple or complex, we will be delighted to help.

783 Longpré St

Sherbrooke, Québec

J1G 4S8

Phone : 819-342-3233

E-Mail : info@t2npowdercoating.com